Commercial, Educational and Trial licenses are available.

What you get

Comprehensive Tool Set of nanoCAD platform

nanoCAD platform provides you with a full set of basic and advanced design tools for creating and editing 2D/3D objects. It offers multiple drawing and editing methods for most geometric elements. nanoCAD platform is the base on which you build a more powerful CAD system to your specifications.

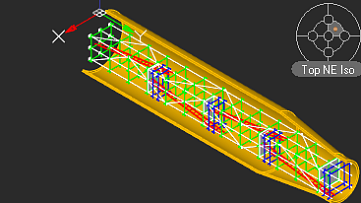

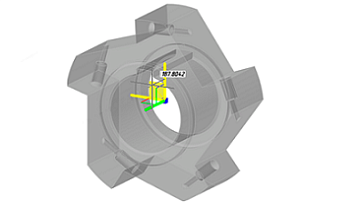

Advanced 3D Tool Set

The 3D Solid Modeling Module offers users the rigor of parametric modeling and the freedom of direct modeling, conveniently packaged together in one environment. Parametric modeling builds 3D geometry piece by piece, with formula-based parameters that specify and change sizes of and distances between parts. Direct modeling offers a what-you-see-is-what-you-get approach in which designers edit 3D models by pushing and pulling faces and edges.

- 3D constraints

- 3D parametric and direct modeling

- History tree

- Assembly tools

- Flat drawings generated from 3D models

- Reads most common CAD formats

- Dynamic UCS

- Full list of features

And

Technical support

Customizable user interface

Open API

Annual updates

New in 3D Solid Modeling

3D History

Presspull

Extrusion

Face Alignment

Stretching by Sections

Parameters Manager

3D Solid Modeling Features

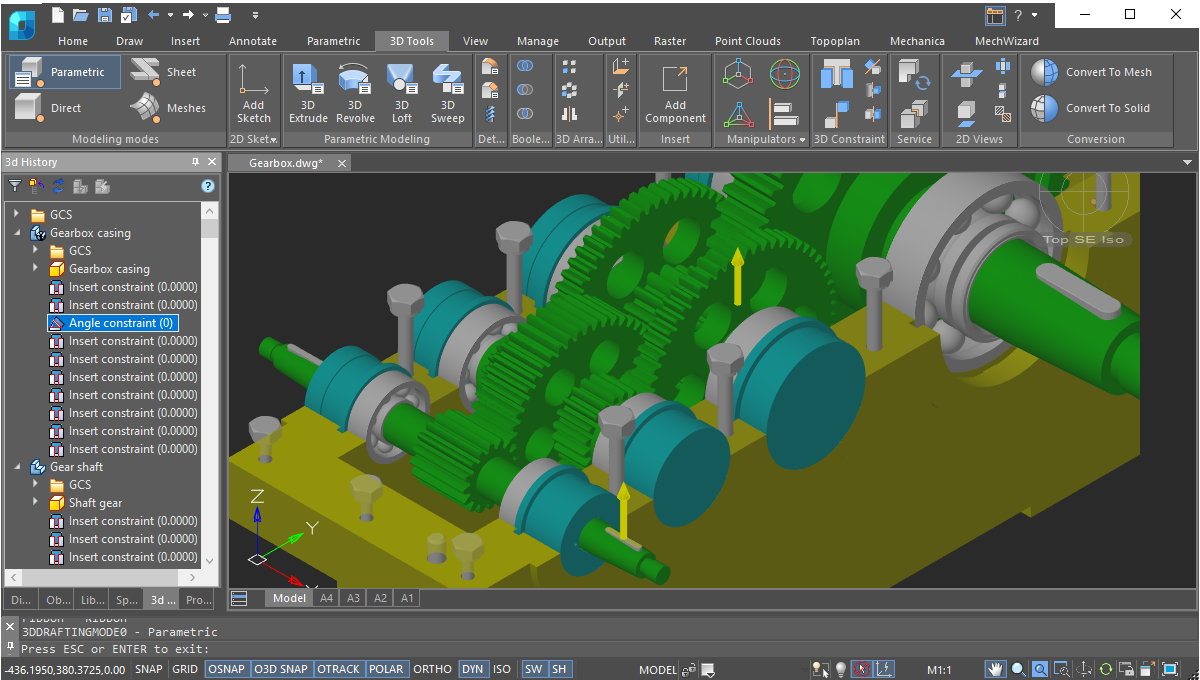

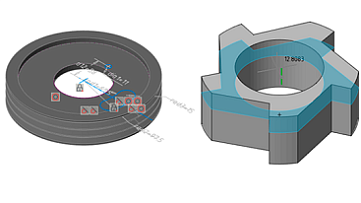

Parametric 3D solid modeling

nanoCAD’s parametric modeling mode allows engineers to build up 3D geometry, piece by piece. This approach to design is common among most MCAD applications, including SolidWorks and Inventor. As 2D sketches are turned into 3D features, engineers document their design intent through constraints and geometric relationships. As each step must follow the series of preceding steps, the parametric approach tends to require careful pre-planning. The history of the model’s construction is recorded by the history tree, which, in nanoCAD, is an Inspector panel with its own set of tools.

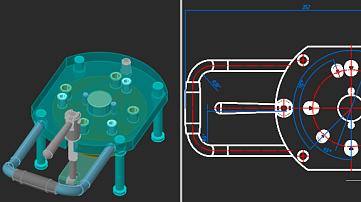

Direct 3D modeling

Natural 3D modeling UI

Associativity of 3D models and drawings

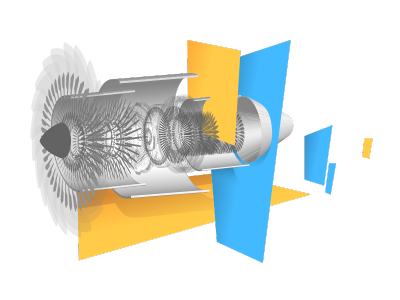

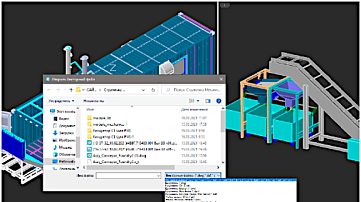

Model exchange via Import/Export

Models created using 3D Module can be exchanged with most CAD systems, exported to 3D printers, CNC machines and web-based viewers. Supported formats are:

- STL for stereolithography;

- Parasolid X_T, X_B for NX, Solid Edge, SolidWorks;

- JT, IGES, STEP - standard engineering data exchange formats;

- SAT, C3D - ACIS and C3D modellers' formats;

- VRML for 3D graphics on the web;

- COLLADA for interactive 3D applications.

Bounding prisms

External references